Your heat exchanger converts flue gas and the other byproducts of combustion into heat for your home, and your furnace transfers that heat throughout your home. The heat exchanger is one of the largest components of your home’s furnace, and it’s also the most expensive to replace. The good news is that if you schedule annual preventive maintenance for your furnace, the heat exchanger might last as long as the furnace itself. However, you shouldn’t delay replacing a damaged heat exchanger because heavy use can create stress fractures and potentially release deadly carbon monoxide (CO) fumes into your home.

Here’s a quick look at how your forced-air heat exchanger works and some frequently asked questions.

How Does Your Heat Exchanger Work?

Just as the name implies, a heat exchanger exchanges thermal energy into radiant heat. In order for heat to flow, there needs to be a temperature difference in order for warm air to flow into the cool areas. Your furnace generates heat in the heat exchanger, and the remaining HVAC systems such as the fans and the ventilation system then work to distribute that heat throughout the home.

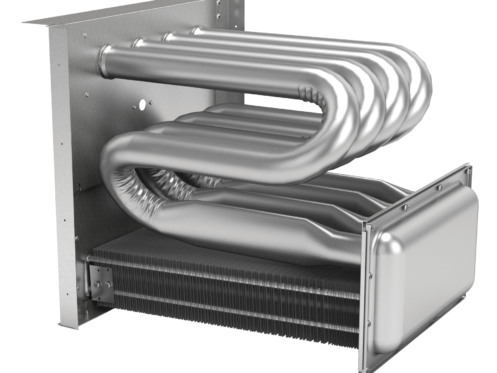

If you were to open up your furnace’s heat exchanger, you’d see elements that get heated up by flue gas similar to the heating elements that you see in your oven. Your furnace burns natural gas or propane, and the combustion process creates an exothermic reaction that subsequently releases heat and gases. During that reaction, the flue gas created in the combustion process travels through your heat exchanger on its way to the exhaust outlet. Your furnace’s fans then proceed to blow and circulate air over the heat exchanger’s exterior, and the heated air is pushed out to your duct system.

What’s the Difference Between Primary and Secondary Heat Exchangers?

When you’re in the market for a new furnace, you’ll probably see advertisements for new high-efficiency furnaces that are over 90% efficient, compared to the 70-80% efficiency rating offered by a traditional forced-air furnace. A high-efficiency furnace is more eco-friendly and offers a longer operational life and immediate energy savings. These advantages are all because a high-efficiency furnace has a secondary heat exchanger that converts energy that would have otherwise been wasted by a conventional furnace.

All furnaces are measured in terms of their Annual Fuel Utilization Efficiency (AFUE) rating. Many older furnaces still in service might only operate at around 65% AFUE. What this means is that 35% of the thermal output created during combustion gets wasted. The primary exchanger in your furnace contains the hottest flue gas found closest to the burners. It’s more likely to have long-term service issues because it’s constantly subjected to flames and extreme heat, which can result in stress fractures, cracks and leaks.

A new furnace is considered high-efficiency if it offers over a 90% AFUE rating, and current high-efficiency units are available that operate with AFUE ratings over 98%. As the combustion exhaust and flue gas exit the primary heat exchanger, it then travels into a secondary heat exchanger where additional heat is released from the flue gas and water vapor begins to form. During condensation, additional latent heat is released, resulting in an even higher efficiency level.

High-efficiency furnaces might also be advertised as condensing furnaces. The secondary heat exchangers found in high-efficiency furnaces are typically made from either stainless steel or a durable and corrosion-resistant coated steel alloy engineered to withstand extreme heat, moisture and even acid. A high-efficiency furnace is also a much more eco-friendly option. It’s a great investment to help you reduce your carbon footprint by virtually eliminating the inefficiencies associated with a traditional forced-air furnace.

How Can I Troubleshoot Problems With My Heat Exchanger?

You probably already know that you should never attempt furnace repairs on your own no matter how handy you might be. But there are certainly some things that you can do on your own to make sure that your heat exchanger and your furnace are in working order. For starters, you should always investigate if any rooms in your home aren’t coming to the proper temperature. That usually indicates an airflow problem, and it’s an easy fix. If you hear rattling or grinding sounds, that usually means that it’s time to schedule a service call. And if you smell gas, you and your family should exit your home immediately and call your utility provider.

Your utility company adds a very distinctive scent to natural gas so that you can smell a gas leak, but carbon monoxide (CO) is completely odorless. Even very small levels of carbon monoxide can be extremely dangerous for both your family and your pets, so be sure to mount CO detectors near your living room and bedrooms and replace the batteries at least every six months. At the beginning and end of every cold season, you should also turn your furnace completely off and make sure that your chimney and exhaust pipes are unobstructed and free from any blockage. Even seemingly cosmetic damage can be a serious safety issue, so be sure to contact a professional right away if you see any damage or experience any other airflow problems.

It’s also almost impossible to identify any service issues with your heat exchanger unless you can perform a combustion analysis/CO test and a visual inspection of the exchanger and its internal elements. A licensed technician will have the proper testing equipment for the CO test and the training to notice any problems or service issues by performing a visual inspection.

How Often Will I Need Furnace Service?

Annual preventive maintenance is the best way to prolong the life of your furnace, and during your service visit, one of our technicians will perform a CO test and a complete visual inspection of your furnace. External furnace damage is easy to spot, and it doesn’t take any training to see a bent or broken pipe or panel. But we also need the ability to look inside the furnace in order to perform a sufficiently thorough inspection.

The good news is that instead of disassembling your furnace or removing any of its parts, we can use a special fiber-optic camera with a flexible shaft that gives us a 360-degree view deep inside your furnace. The fiber-optic camera enables us to locate internal issues deep inside your furnace’s heat exchangers and determine if any further repairs will be necessary. The combustion analysis and CO test won’t usually require technicians to get into any otherwise inaccessible areas of your furnace, but it does require specialty tools. Your annual maintenance visit is a great way to prolong your furnace’s life and improve its efficiency, and you’ll be able to enjoy peace of mind all yearlong!

Our licensed and bonded technicians are always a phone call away when you need quality HVAC services. Contact Reliable Air Conditioning today for professional furnace services or if you would like a quote on professional furnace installation in Mesa or a surrounding area. We also perform air conditioning services as well as indoor air quality assessments.